Technical Guarantee Section

Since 1999, our track record speaks for itself: quality, guarantee and commitment to you and our community. Before getting into your hands, each of our products undergoes rigorous testing to ensure it meets the highest standards. In addition, we carefully choose the best materials to assure durability.

We are so confident in the quality of our products and materials that many of them have extended warranty periods.

Below is detailed information about our warranties, the service life of our products and the different environmental conditions that can affect the materials.

At TecroStar, from our very beginnings we have been dedicated to assuring the highest quality standards in each of our products. We are proud to say that we are pioneers in the industry; we are the only Spanish company dedicated to researching, designing, manufacturing and installing removable mezzanines for all types of use.

During this time, we have maintained close contact with our community to identify areas for improvement, allowing us to tailor our products to their needs.

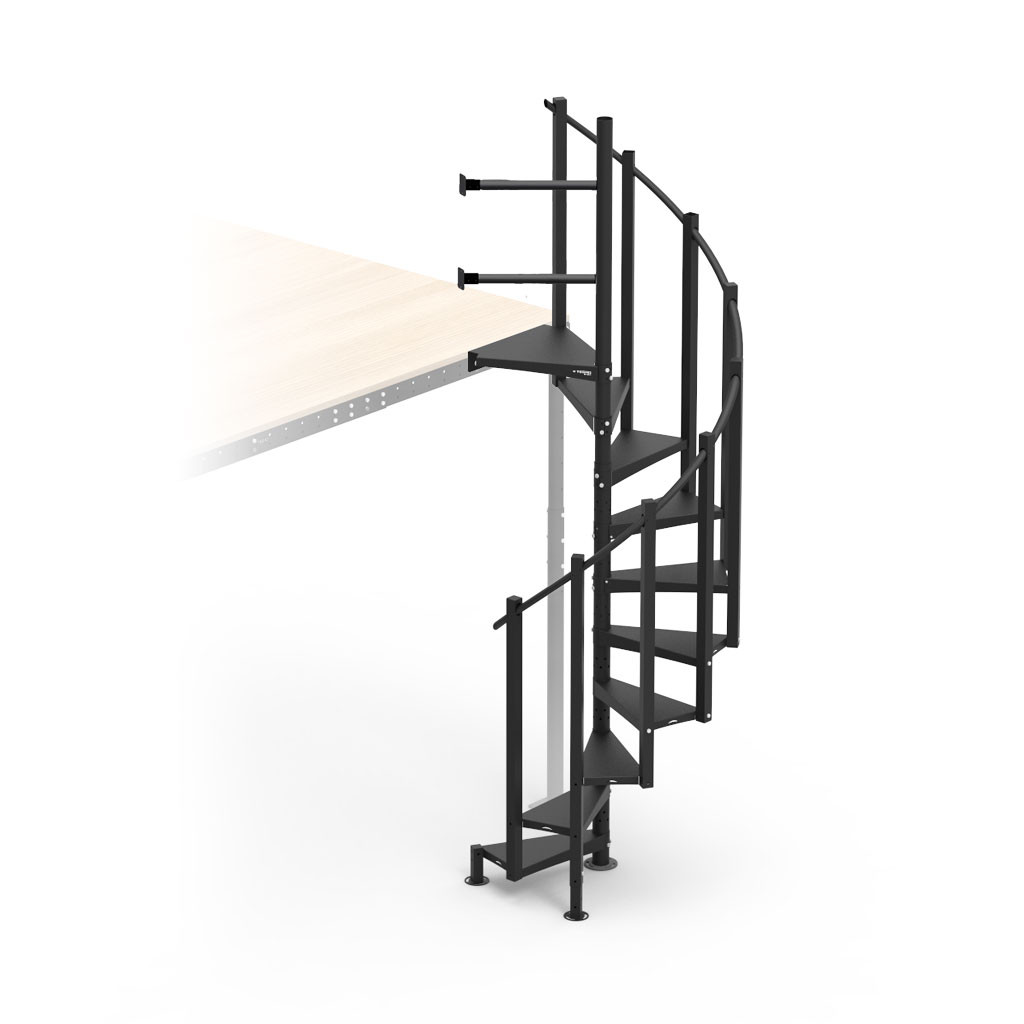

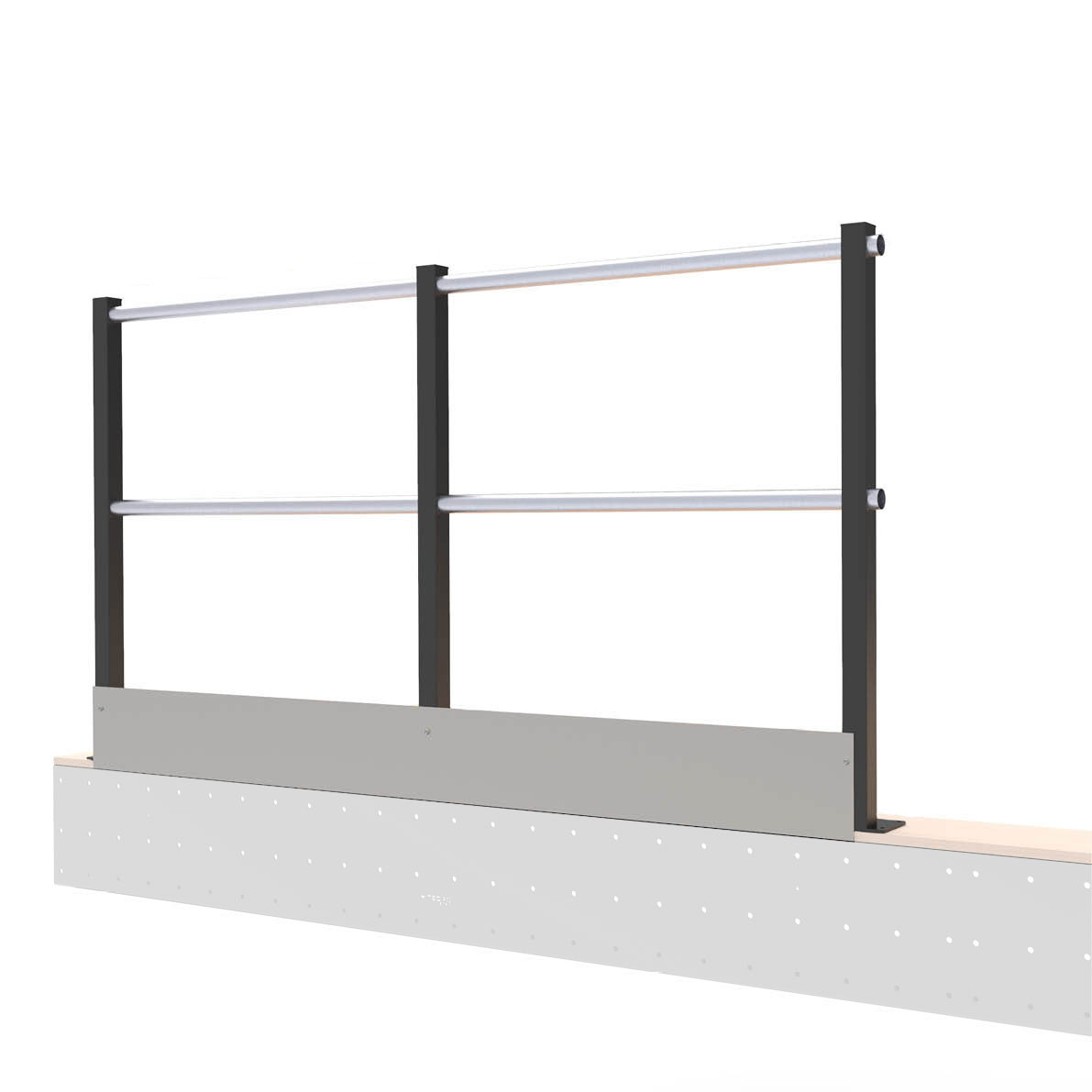

We design the products with the strictest European and international standards in mind, using Eurocodes EN 1990, EN 1991, EN 1993 and EN 1995 for the structures and other relevant regulations, such as ISO 14122, for ladders and accessories, along with other more specific local or national regulations. In addition, we apply various load and material safety coefficients to ensure the reliability and strength of our structures.

We conducted an initial feasibility study followed by a detailed design of the prototype. Then, we used various 3D mechanical design and structural calculation programmes. Finally, we installed and tested the prototype in our test area, looking for possible improvements before standardisation and publication.

In addition, we are proud to have patents that legally support our products both nationally and internationally, demonstrating our commitment to innovation and intellectual property protection.

Throughout these years, we have had the privilege of collaborating with customers from various industries. These include well-known names like Amazon, Primark, Seat-Volkswagen, BMW, Airbus, Kawasaki, Tuc Tuc, AR Sistemas, Harley Davidson, KTM Bizkaia, Ulma, Gas Monkey, Ead Casa and others.

We are proud to say that we have created more than 610,000 m2 of additional surface area, taking advantage of the height of our customers' spaces. More than 16,000 Tecrostar mezzanines sold are our guarantee.